Sustainability and Energy Resilience: Mission Possible

Tecnocap, multinational metal packaging company, specialized in the industrial production of Metal Closures for glass and plastic containers, Aluminium Aerosol and Bottles widely used for food, beverages, spirits and in the cosmetic, nutraceutical and pharmaceutical sectors, improves sustainability and energy resilience thanks to the cogeneration system installed at the production plant in Lecco, Italy.

The Group operates with eight production plants in six different countries, commercial offices around the world and three research centres in the USA and Europe, as well as having .It recently signed a joint venture that marks the entry also into the Indian and Far East market. Today Tecnocap moves a turnover of about 200 million Euros and has over 900 employees.

“Metal packaging is infinitely recyclable and is itself an icon of the circular economy” explains Michelangelo Morlicchio, CEO of the Tecnocap Group. “Since its foundation, Tecnocap’s organizational culture has been oriented to the constant search for innovative solutions able to harmonize sustainability and growth“.

During the structural redevelopment and modernization of the Lecco facility, a factory built at the beginnings of the 20th century, Tecnocap decided to give priority to technological upgrade, sustainability and energy resilience, in the full respect of the architectural historical heritage, .

With its about 35,000 square metres and 90 employees, in the last two years the Lecco plant recorded two-digit increases in production requiring a higher level of efficiency in energy management, especially to obtain the necessary retaining force which ensures the continuity of production.

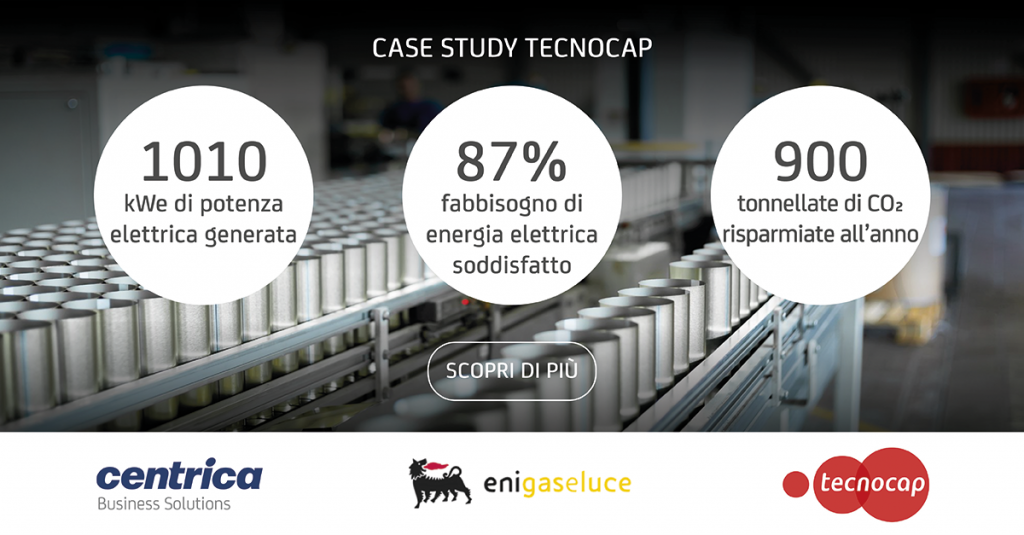

After a preliminary feasibility study and a project engineering phase conducted six hands by the partners, the cogeneration system installed in Lecco will allow at the same time an energy upgrade and a strong reduction in CO2 emissions.

“The choice of Centrica Business Solutions as a technological supplier is the result of the consolidated relationship with Eni Gas e Luce, a privileged partner of our energy strategy in Italy and the need to build a turnkey cogeneration plant, capable of achieving the ambitious objectives of energy efficiency and independence, adapting perfectly to our production cycle“. Michelangelo Morlicchio CEO of the Tecnocap Group.

In addition to the reduction in consumption, the company estimates a significant reduction in CO2 emissions of 900 tonnes equivalent and a cut of 380 tonnes of oil equivalent: very important parameters for a company that this year publishes its first Sustainability Report. Another added value of the investment is the positive impact on the energy resilience capacity of the plant that, thanks to Centrica Business Solution, can continue to operate even in case of malfunctions or maintenance of the public electricity grid.

“The cogeneration plant will make us less dependent on the grid and any power outages“, comments Michelangelo Morlicchio, Tecnocap CEO and Founder “to guarantee operational continuity and maximum production efficiency towards our customers“